"From design to finished product, without intermediate steps."

At DMP, we oversee every phase of the work, from the initial design to the creation of the finished product. This allows us to reduce lead times, maintain control over quality, and offer a complete, reliable, and customized service. Whether you need a single component or a series supply, we handle everything for you.

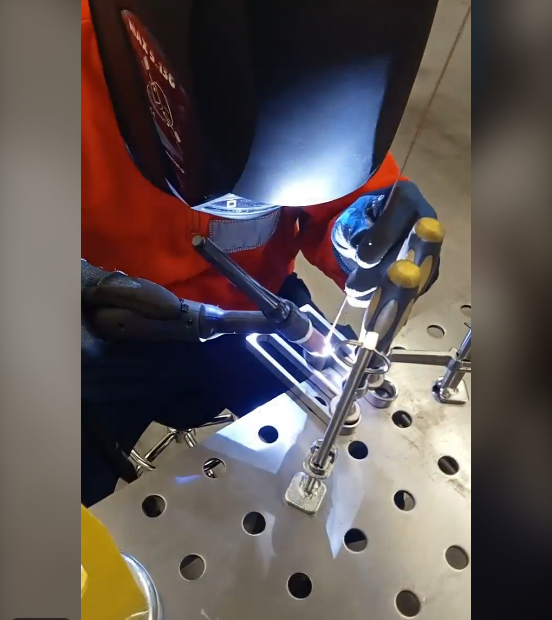

Welding

"We perform precise and functional welds for metal structures, frames, and assembled components. We work with iron, steel, aluminum, and other metals, ensuring joint strength and cleanliness."

Automatic Cutting

"We cut round bars, squares, profiles, and rods with precision from 0° to 60°, up to a maximum diameter of 260 mm. We use automatic systems to ensure speed, repeatability, and consistent tolerances, even on large batches."

Component Assembly

"We complete the production cycle with the final assembly of parts, modules, frames, and machinery. We offer a 360° service, taking care of every detail to deliver ready-to-use solutions, reducing time and steps for the customer."

Design

"We assist the client from the very first stages, offering support in the design of components, frames, and metal structures. We optimize the design to ensure functionality, ease of production, and cost savings."

Bending

"We perform precise bending on tubes, rods, profiles, and sheets, even in series. We work with different geometries and materials, ensuring repeatability, cleanliness, and tight tolerances on each piece."

Surface Treatments

"Thanks to qualified partners, we offer surface treatments such as painting, galvanizing, sandblasting, and other finishes upon request. A complete service, with no worries for the customer."